hpmc chemical uses

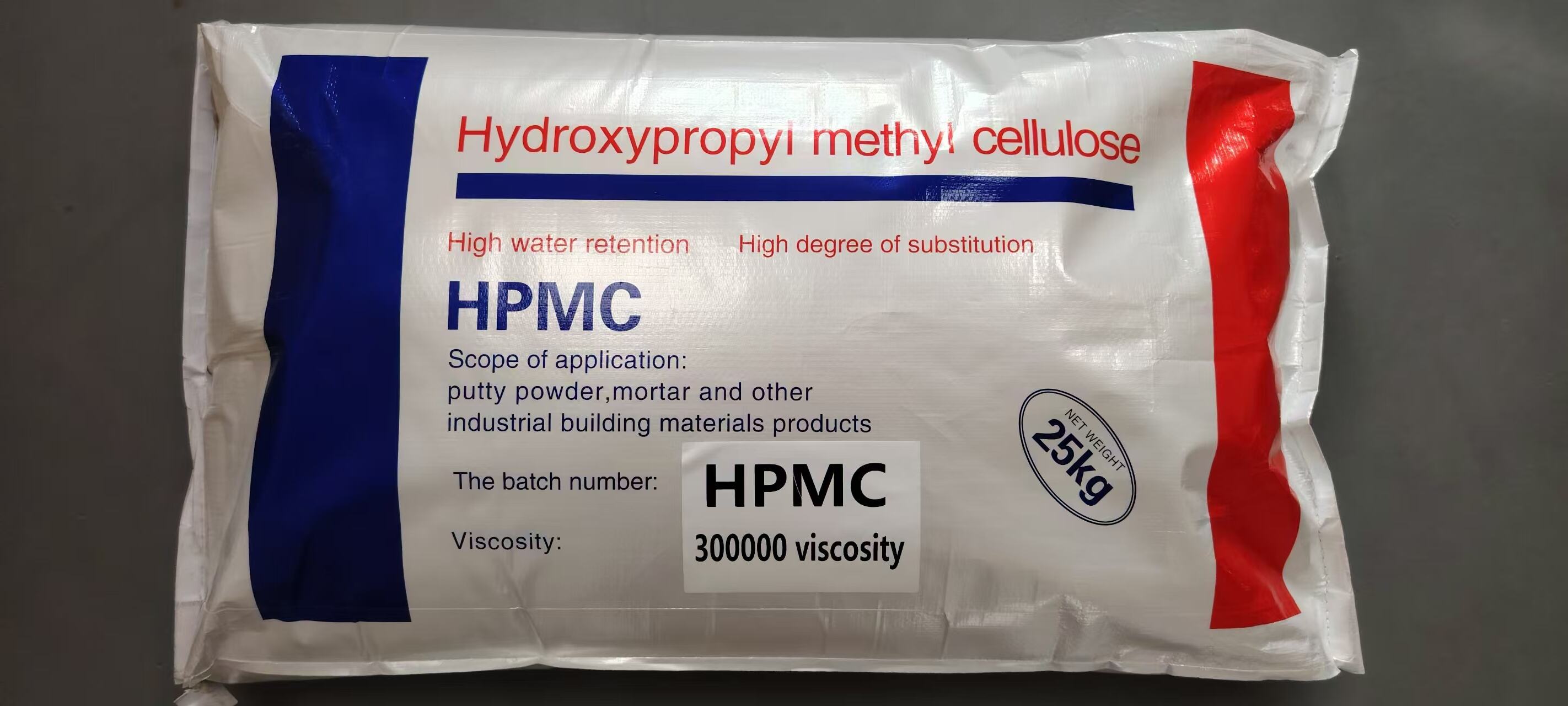

Hydroxypropyl methylcellulose (HPMC) stands as a versatile chemical compound with extensive applications across various industries. This cellulose derivative combines exceptional properties that make it indispensable in pharmaceutical, construction, and food industries. In pharmaceutical applications, HPMC serves as a crucial ingredient in controlled-release drug delivery systems, tablet coatings, and ophthalmic solutions. Its ability to form clear, stable films and act as a binding agent makes it particularly valuable in tablet formulation. In the construction sector, HPMC functions as a highly effective water-retention agent and rheology modifier in cement-based materials, improving workability and adhesion properties. The food industry utilizes HPMC as an emulsifier, stabilizer, and thickening agent, enhancing product texture and stability. Its unique thermal gelation properties allow it to function as a vegetarian alternative to gelatin in food products. Furthermore, HPMC demonstrates excellent film-forming capabilities, making it valuable in protective coatings and packaging materials. The compound's non-toxic nature, biodegradability, and broad compatibility with other materials have established it as a preferred choice in sustainable product development across multiple sectors.