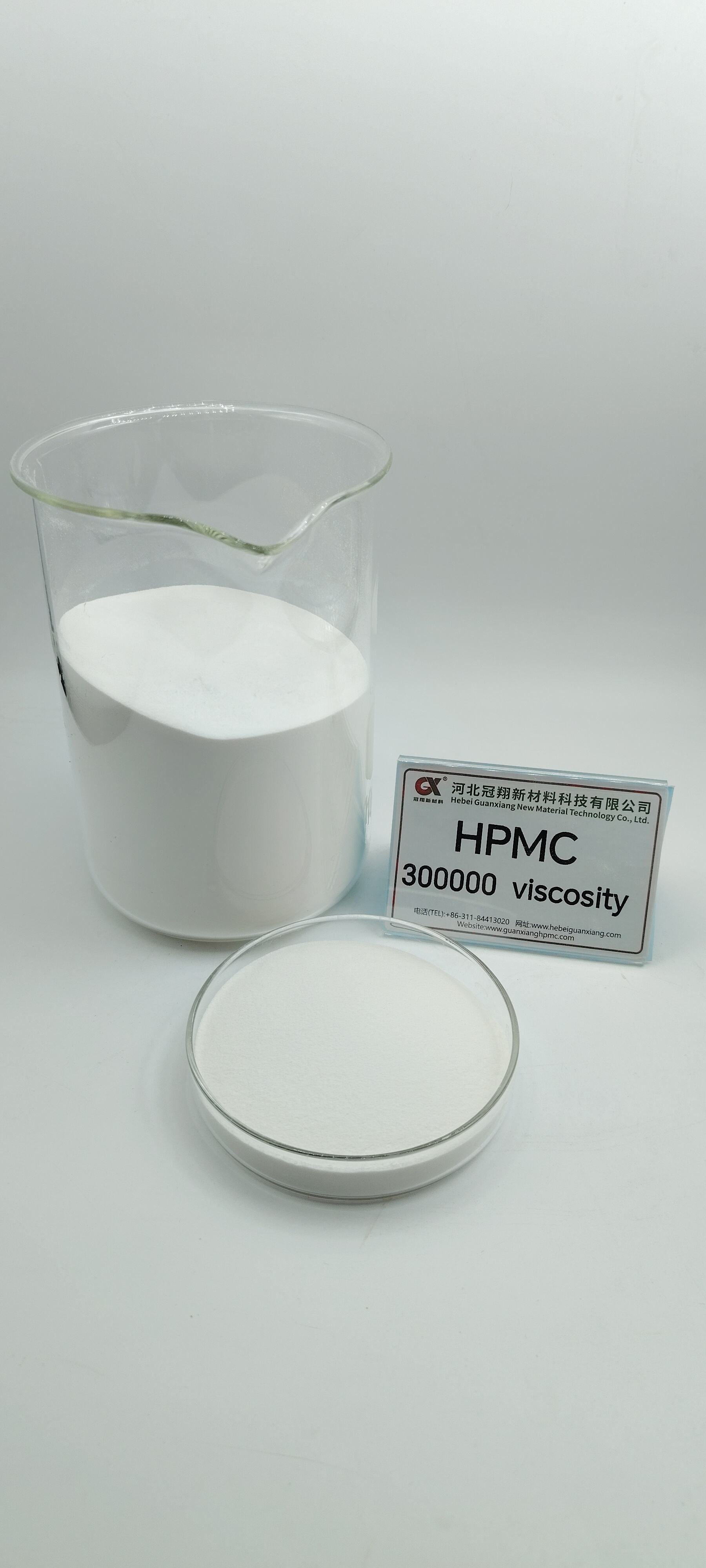

hpmc hydroxypropyl methylcellulose manufacturer

A leading HPMC hydroxypropyl methylcellulose manufacturer stands at the forefront of producing this versatile cellulose ether derivative. The manufacturing facility utilizes advanced production techniques and strict quality control measures to create HPMC that meets international standards. The production process involves the chemical modification of cellulose, resulting in a product that offers excellent film-forming properties, water retention capabilities, and binding characteristics. The manufacturer employs state of the art equipment and automated systems to ensure consistent product quality and efficient production cycles. Their expertise extends to creating various grades of HPMC suitable for different applications, including construction materials, pharmaceutical products, food additives, and personal care items. The facility maintains ISO certifications and follows Good Manufacturing Practices (GMP), ensuring that all products meet regulatory requirements and customer specifications. With an annual production capacity of several thousand metric tons, the manufacturer can accommodate both small batch orders and large scale industrial demands, while maintaining product consistency and quality across all production runs.