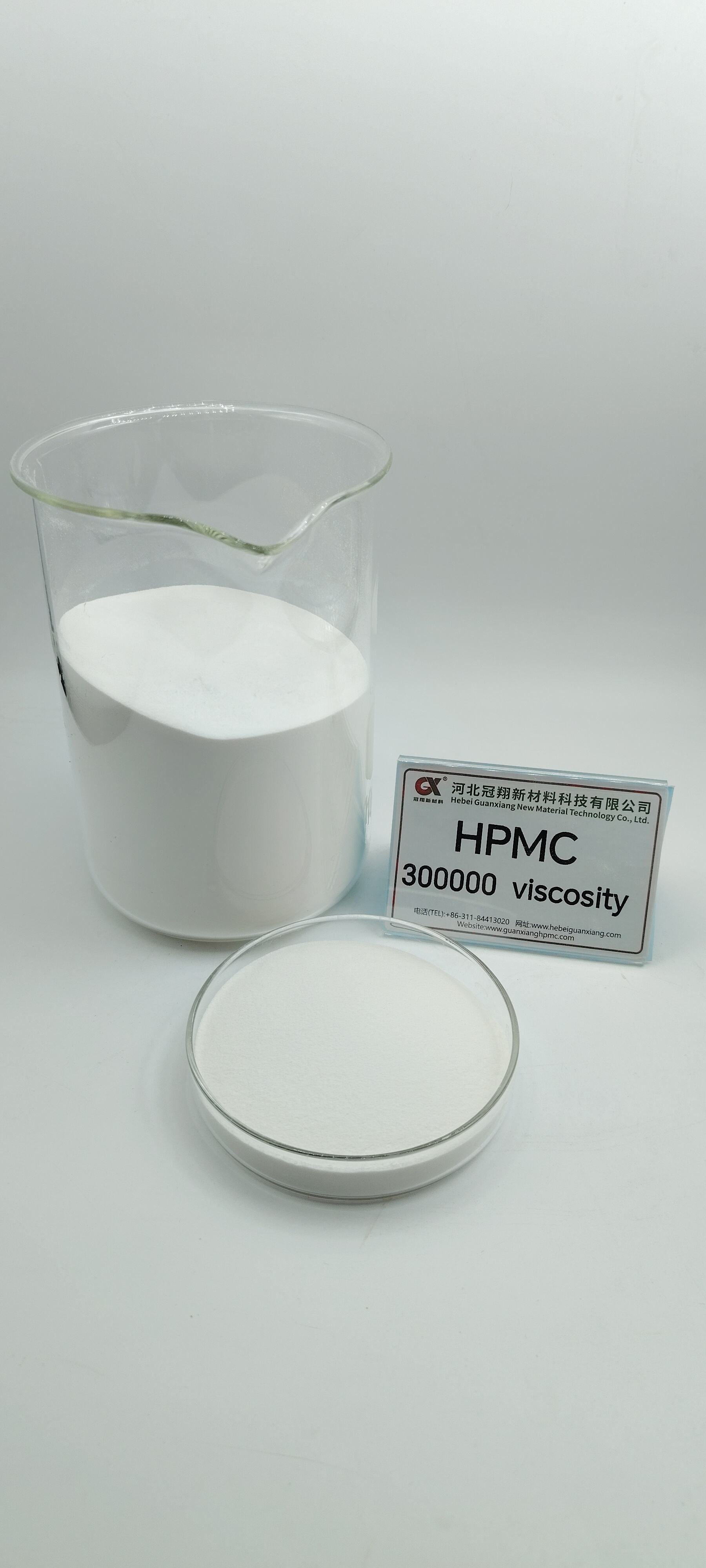

hpmc types manufacturer

A HPMC types manufacturer specializes in producing hydroxypropyl methylcellulose, a versatile cellulose derivative that plays a crucial role in various industries. These manufacturers employ advanced production technologies to create different grades and specifications of HPMC, ensuring consistent quality and performance. The manufacturing process involves careful control of substitution degrees, viscosity levels, and particle sizes to meet diverse application requirements. Modern HPMC manufacturers utilize sophisticated quality control systems and automated production lines to maintain product stability and reliability. They offer comprehensive product ranges including pharmaceutical grades for drug formulations, construction grades for building materials, and food grades for dietary applications. The facilities typically feature state-of-the-art research and development centers, enabling continuous product innovation and customization capabilities. These manufacturers maintain strict compliance with international quality standards and regulatory requirements, including GMP, ISO, and FDA guidelines. Their production capabilities often include multiple manufacturing lines capable of producing various HPMC types with different molecular weights and substitution patterns, allowing them to serve diverse market demands efficiently.