hpmc uses manufacturer

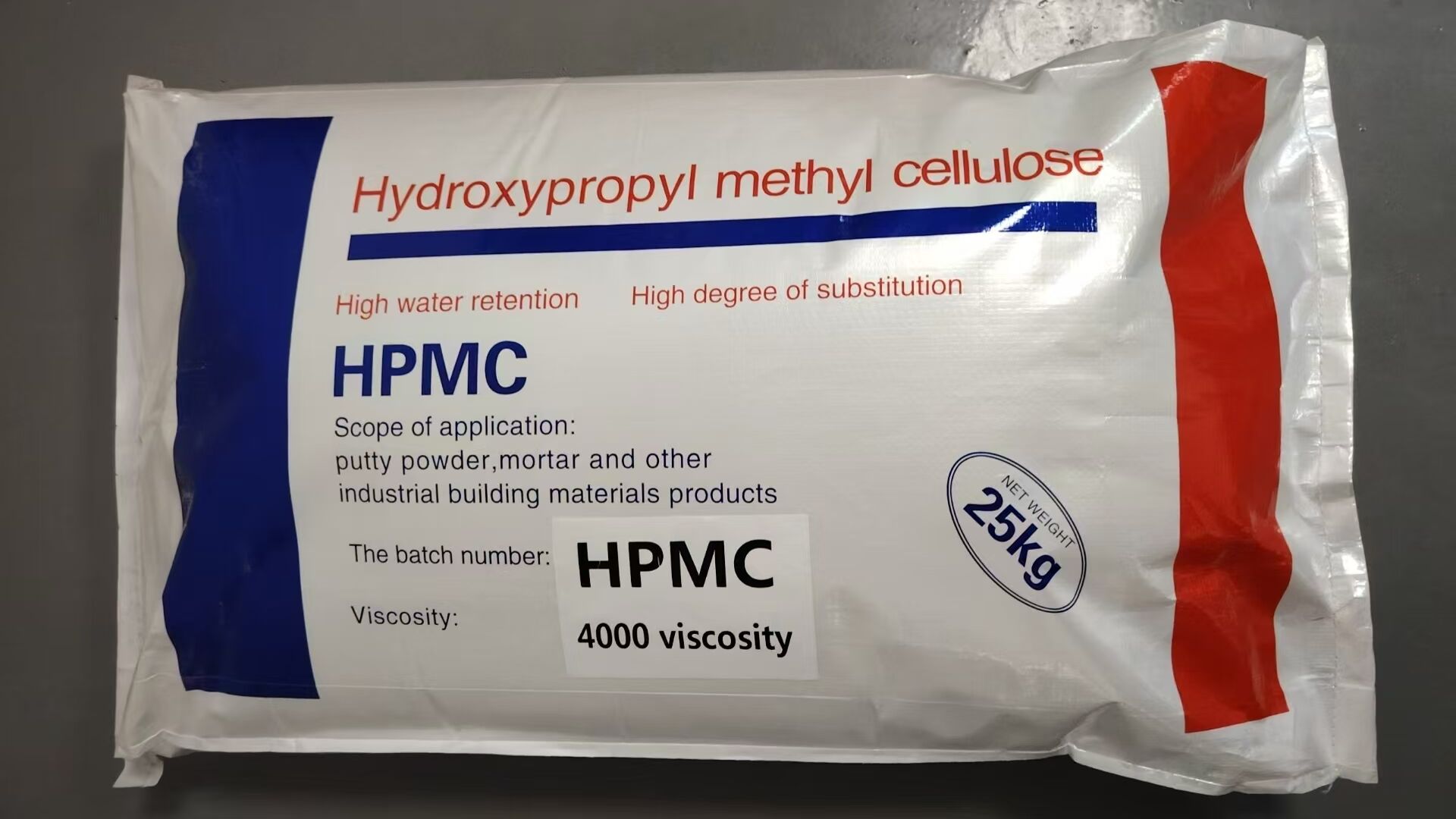

A HPMC uses manufacturer specializes in producing hydroxypropyl methylcellulose, a versatile polymer used across various industries. These manufacturers employ advanced production technologies and quality control systems to ensure consistent product quality. Their facilities are equipped with state-of-the-art processing equipment capable of producing HPMC in different viscosity grades and specifications. The manufacturing process involves careful control of temperature, pressure, and reaction conditions to achieve desired product characteristics. Modern HPMC manufacturers implement automated systems for precise material handling and process monitoring, ensuring optimal production efficiency and product consistency. They maintain strict compliance with international quality standards and regulatory requirements, particularly important for pharmaceutical and food-grade HPMC production. These facilities often feature dedicated research and development departments that work on product innovation and customization to meet specific customer requirements. Environmental sustainability is increasingly emphasized, with manufacturers implementing eco-friendly production processes and waste management systems. The production capabilities typically include various HPMC grades suitable for construction materials, pharmaceutical excipients, food additives, and personal care products. Quality assurance laboratories equipped with advanced analytical instruments ensure that each batch meets specified parameters.