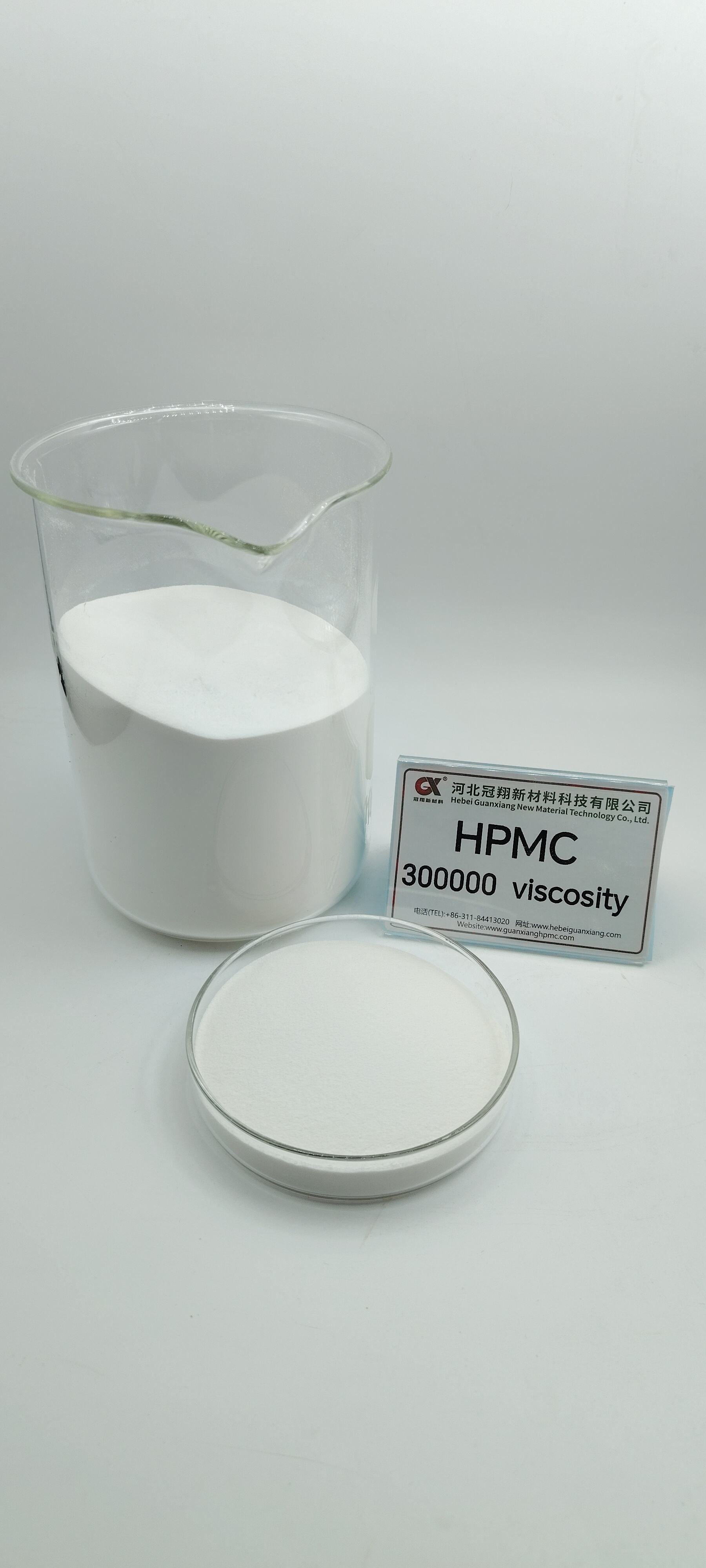

china hpmc cellulose

China HPMC (Hydroxypropyl Methylcellulose) cellulose is a versatile and advanced chemical derivative of cellulose that has revolutionized various industries. This modified cellulose ether combines the properties of both hydroxypropyl and methyl substitution groups, resulting in a highly functional polymer. The material exhibits exceptional film-forming capabilities, surface activity, and water retention properties, making it indispensable in construction, pharmaceuticals, and food industries. In construction applications, China HPMC cellulose serves as an essential additive in cement-based materials, improving workability, water retention, and adhesion strength. Its unique molecular structure allows for controlled viscosity and excellent binding properties, ensuring consistent performance in various environmental conditions. The pharmaceutical industry utilizes China HPMC cellulose as a crucial ingredient in drug formulations, particularly in controlled-release medications and tablet coating applications. Its non-toxic nature and stability make it an ideal choice for food applications, where it functions as a thickener, stabilizer, and emulsifier. The material's production in China adheres to strict quality standards, ensuring consistent product performance and reliability across different applications.