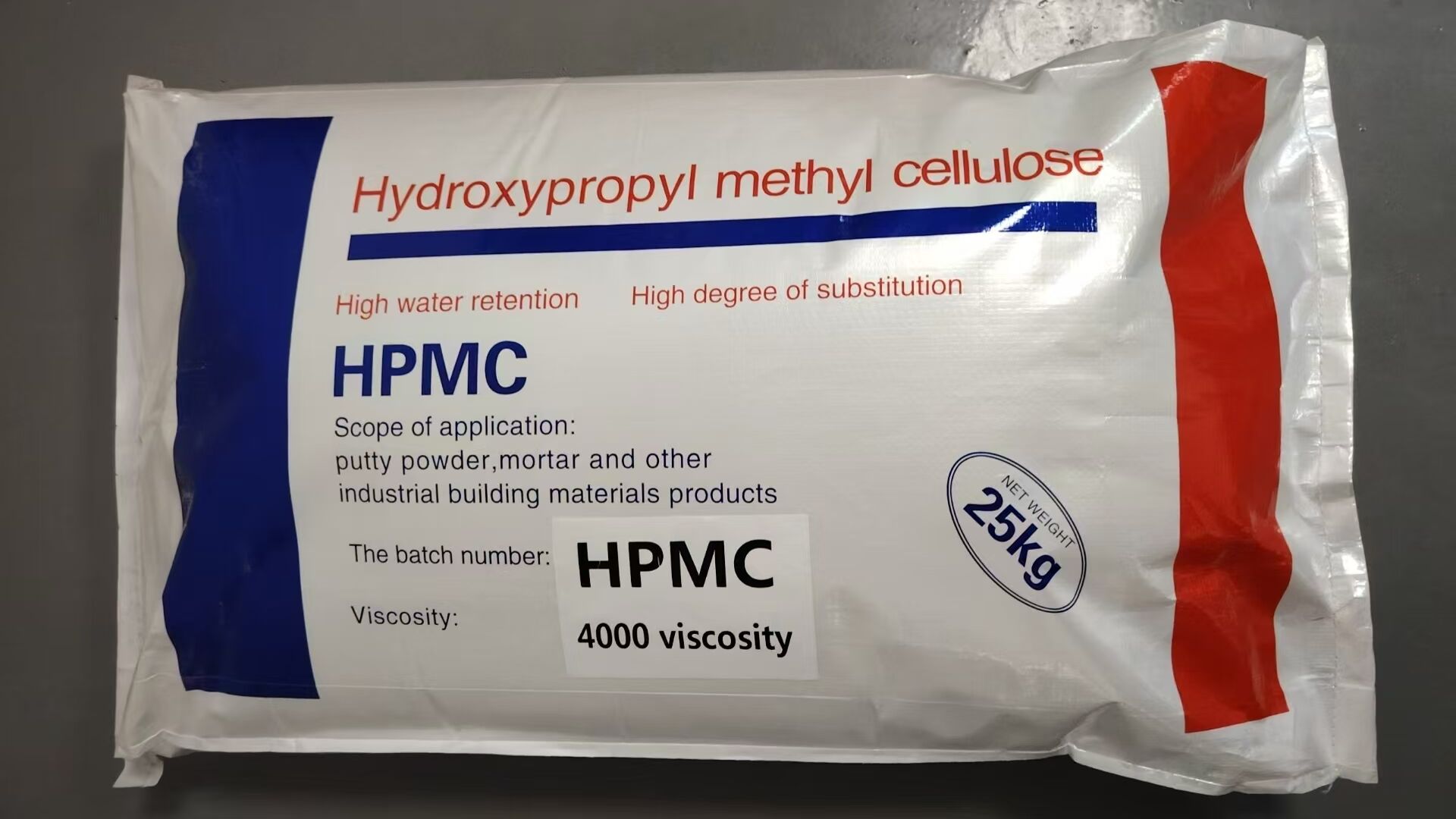

hpmc k100

HPMC K100, or Hydroxypropyl Methylcellulose K100, is a versatile pharmaceutical excipient and industrial polymer that plays a crucial role in various applications. This high-performance compound is characterized by its exceptional film-forming properties and controlled release capabilities. As a premium grade cellulose ether, HPMC K100 exhibits remarkable stability across different temperature ranges and pH levels, making it an ideal choice for pharmaceutical formulations. The polymer's unique molecular structure allows it to form clear, tough, and flexible films that provide excellent barrier properties. In pharmaceutical applications, HPMC K100 serves as a reliable matrix for controlled release tablets, ensuring consistent drug delivery over extended periods. Its solubility characteristics enable it to function effectively in both aqueous and organic systems, providing formulators with greater flexibility in product development. The material's thermal gelation properties make it particularly valuable in modified release formulations, where precise control over drug release kinetics is essential. Additionally, HPMC K100 demonstrates exceptional binding and film-coating properties, contributing to improved tablet stability and appearance. Its versatility extends to food applications, where it serves as a thickener, stabilizer, and emulsifier, meeting stringent regulatory requirements for food-grade materials.