headcel hpmc manufacturer

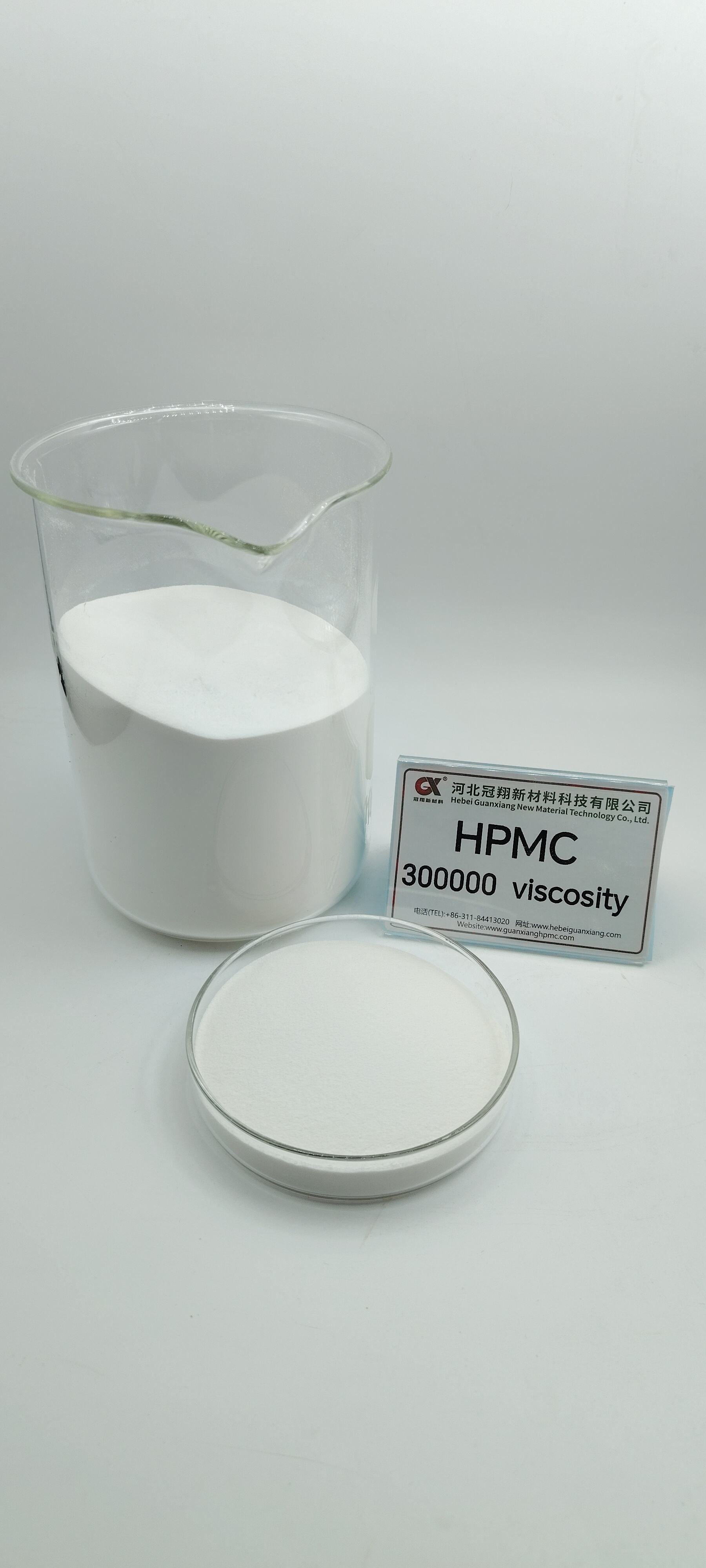

The headcel HPMC manufacturer stands at the forefront of hydroxypropyl methylcellulose production, utilizing advanced manufacturing processes to create high-quality cellulose derivatives. This state-of-the-art facility combines innovative technology with precise quality control measures to produce HPMC products that meet diverse industrial requirements. The manufacturing plant features automated production lines equipped with sophisticated monitoring systems that ensure consistent product quality. The facility's production capabilities extend across various HPMC grades, from low to high viscosity, catering to applications in construction, pharmaceuticals, and food industries. The manufacturer employs a cutting-edge purification system that removes impurities and ensures product stability. With an annual production capacity exceeding 10,000 tons, the facility maintains stringent quality standards through comprehensive testing laboratories and advanced analytical equipment. The manufacturer's commitment to sustainability is evident in its implementation of eco-friendly processes and energy-efficient systems, reducing environmental impact while maintaining productivity. Their research and development department continuously works on product innovation and process optimization, ensuring the manufacturer stays ahead of market demands and technological advancements.