hpmc 2208

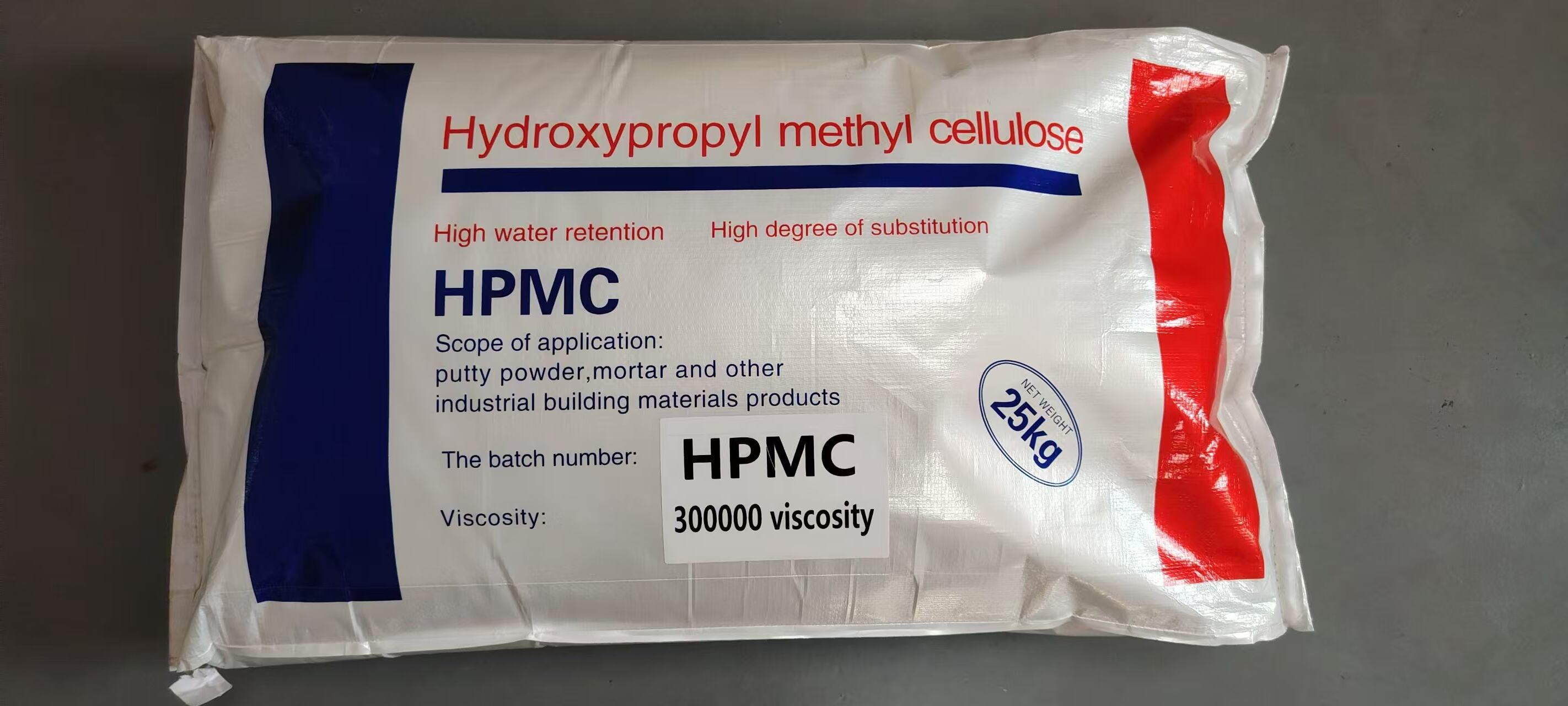

HPMC 2208, also known as Hypromellose 2208, is a versatile pharmaceutical excipient and polymer derived from cellulose. This sophisticated compound features specific chemical modifications that make it invaluable in various pharmaceutical and industrial applications. With its molecular structure carefully engineered to provide optimal performance, HPMC 2208 exhibits remarkable properties including controlled viscosity, excellent film-forming capabilities, and superior stability across diverse environmental conditions. In pharmaceutical formulations, it serves as a crucial component in controlled release drug delivery systems, where it creates a precise matrix that regulates the release of active pharmaceutical ingredients. The compound's unique molecular weight distribution and substitution pattern enable it to form robust hydrophilic matrices when exposed to aqueous environments, facilitating controlled drug release over extended periods. Beyond pharmaceuticals, HPMC 2208 finds extensive use in food applications, construction materials, and personal care products. Its ability to function as a thickening agent, stabilizer, and film former makes it an essential ingredient in many modern formulations. The material's compatibility with various other excipients and its consistent performance under different processing conditions have established it as a standard choice in pharmaceutical development and manufacturing processes.