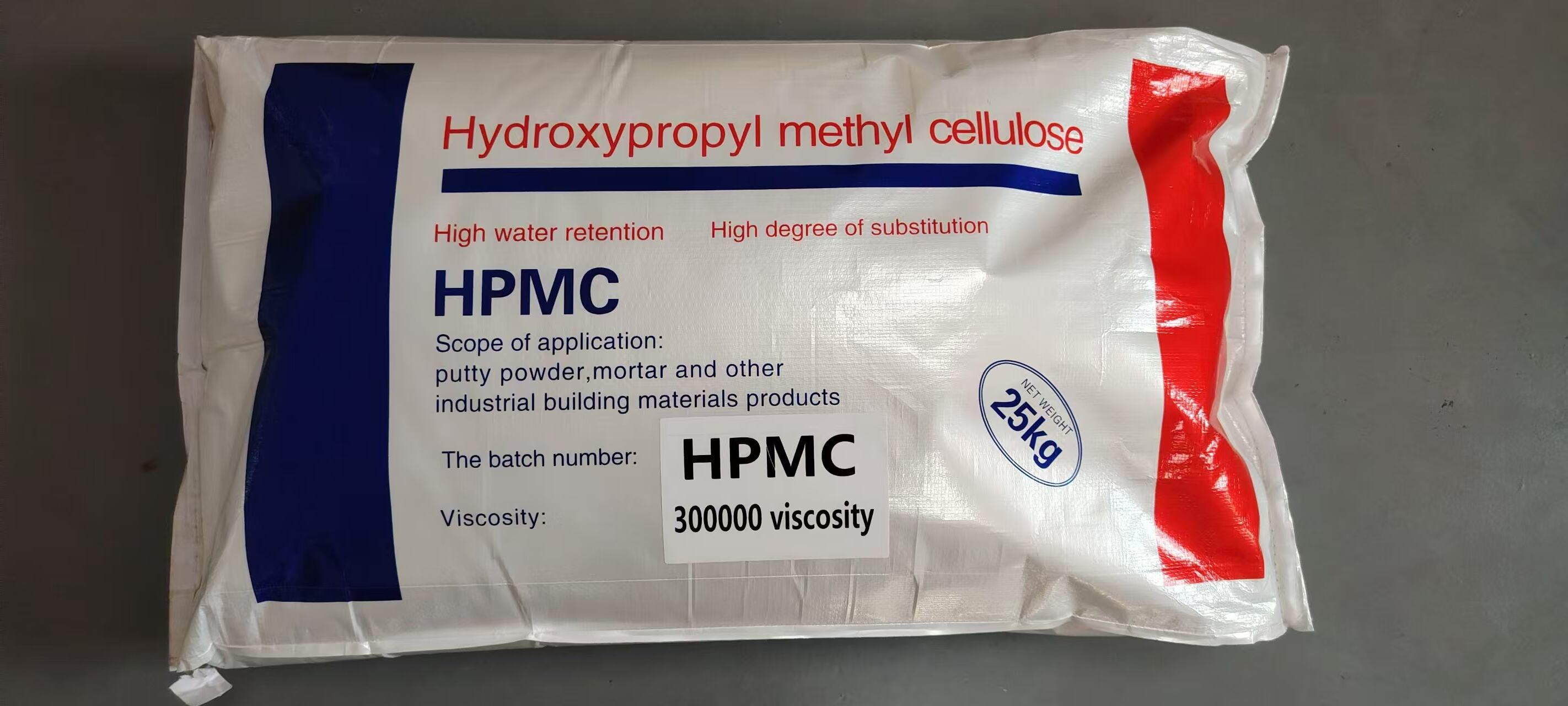

hpmc hydroxypropyl methylcellulose

HPMC (Hydroxypropyl Methylcellulose) is a versatile cellulose derivative that serves as a crucial component in various industries. This semi-synthetic polymer is created through the modification of cellulose, resulting in a compound that exhibits both thermal gelation and surface-active properties. As a multipurpose additive, HPMC functions as an emulsifier, thickening agent, and stabilizer in numerous applications. Its unique molecular structure allows it to form consistent solutions in both hot and cold water, making it invaluable in construction materials, pharmaceutical formulations, and food products. The compound demonstrates exceptional film-forming capabilities, controlled release properties, and superior binding characteristics. In the construction industry, HPMC acts as a water-retention agent and rheology modifier in cement-based materials, enhancing workability and adhesion. In pharmaceuticals, it serves as a crucial excipient in tablet formulation, providing controlled release properties and improving drug bioavailability. The food industry utilizes HPMC as a thickener and stabilizer, benefiting from its ability to maintain product consistency and extend shelf life. Its technological features include adjustable viscosity, excellent stability across various pH levels, and compatibility with numerous other ingredients.