hydroxypropyl methylcellulose benefits

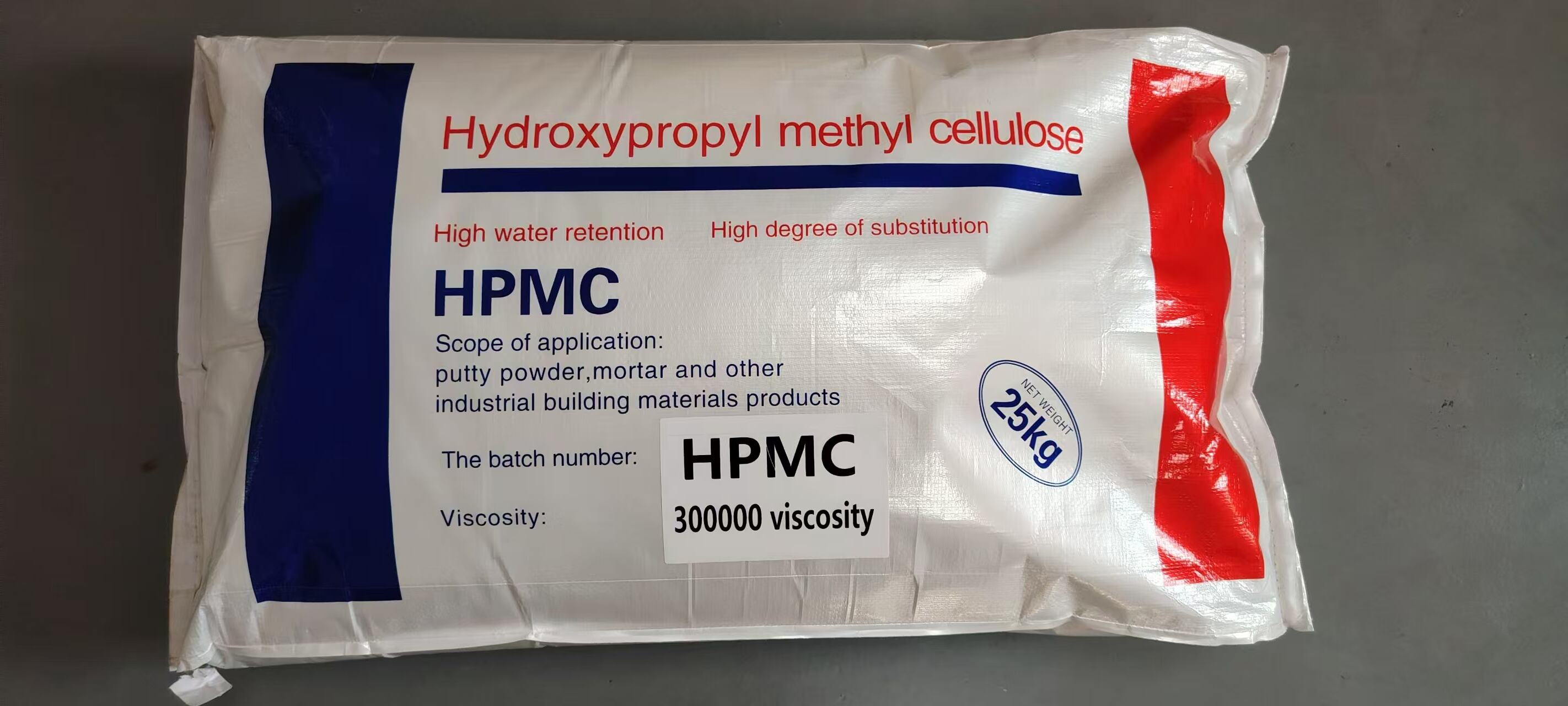

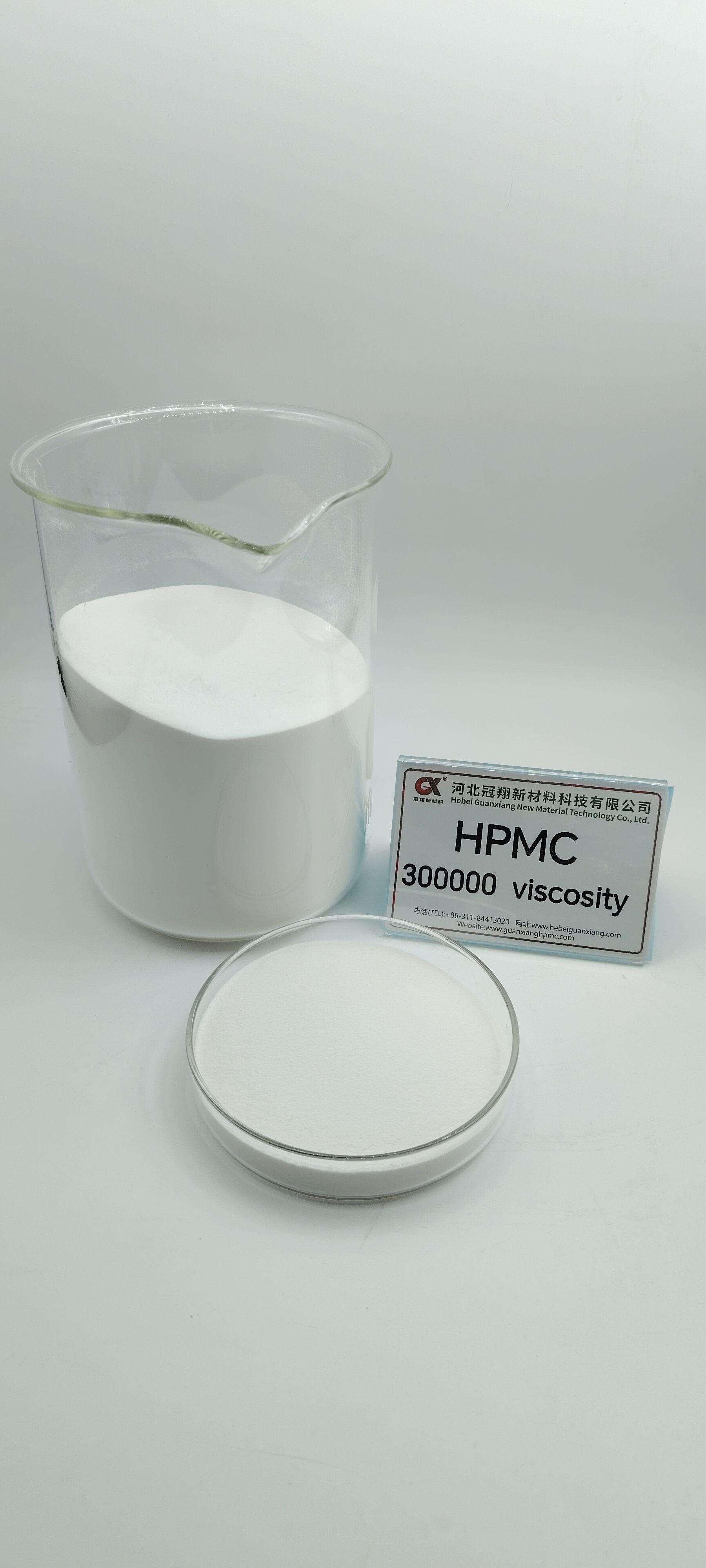

Hydroxypropyl methylcellulose (HPMC) stands as a versatile pharmaceutical excipient and industrial additive that offers numerous benefits across various applications. This modified cellulose derivative combines exceptional film-forming properties with remarkable stability characteristics, making it invaluable in pharmaceutical, construction, and food industries. HPMC demonstrates superior water solubility and creates clear, flexible films that provide excellent oxygen and moisture barrier properties. In pharmaceutical applications, it serves as an effective controlled-release agent, enabling precise drug delivery systems and ensuring optimal therapeutic outcomes. The material's thermal gelation properties make it particularly useful in food applications, where it functions as a thickener, stabilizer, and emulsifier. In construction, HPMC enhances cement-based materials' workability and water retention, leading to improved product performance. Its non-toxic nature and biocompatibility make it safe for human consumption and environmentally friendly applications. The material's ability to maintain stability across various pH levels and temperature ranges further extends its utility in different processing conditions.