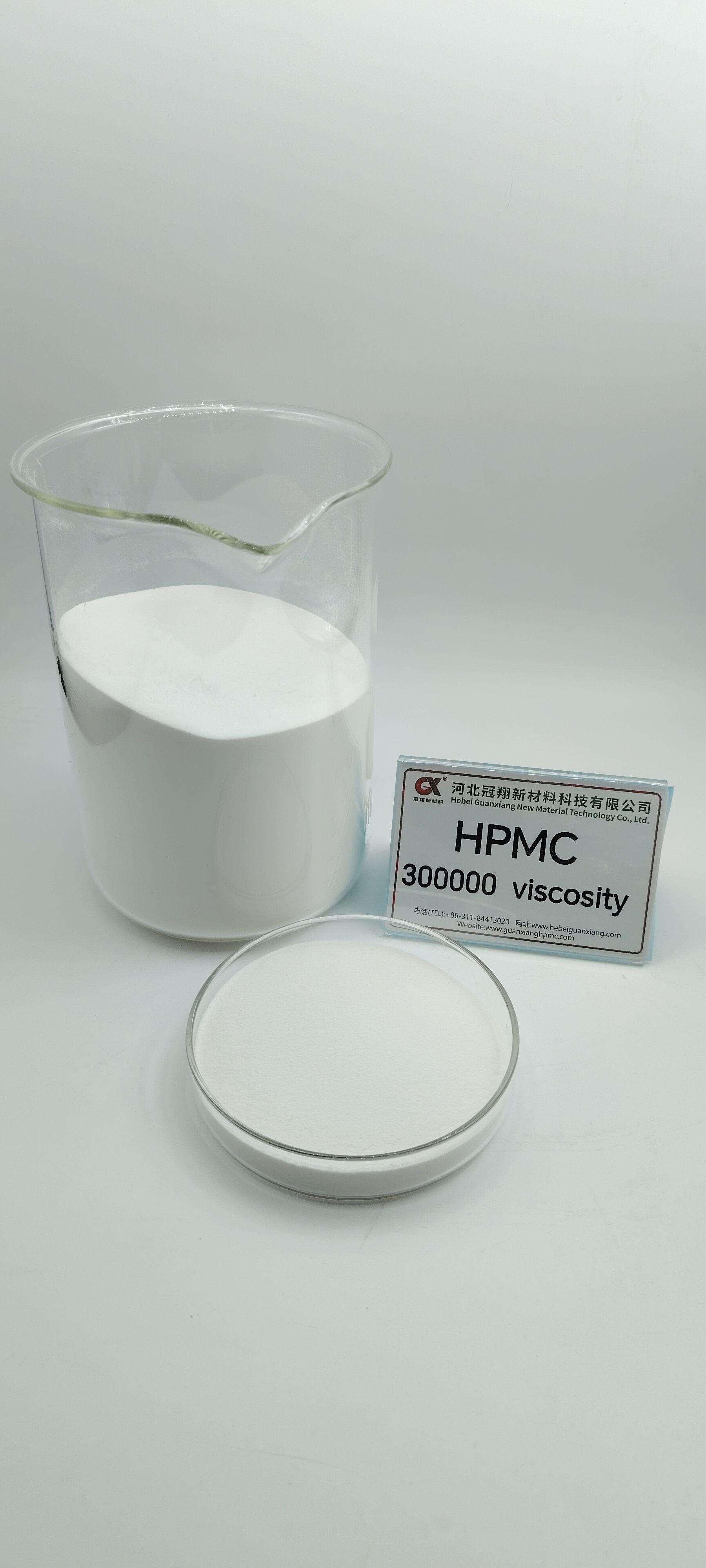

hydroxypropyl methylcellulose function

Hydroxypropyl methylcellulose (HPMC) is a versatile modified cellulose compound that serves multiple critical functions across various industries. This remarkable substance functions as a highly effective thickening agent, binder, film former, and stabilizer in numerous applications. In pharmaceutical applications, HPMC plays a crucial role in controlled-release drug delivery systems, where it forms a gel matrix that regulates the release of active ingredients. Its unique molecular structure allows it to create consistent viscosity in aqueous solutions, making it invaluable in food and beverage applications. In construction, HPMC functions as a crucial additive in cement-based materials, improving water retention, workability, and adhesion properties. The compound's ability to form clear, flexible films makes it essential in coating applications, while its temperature-responsive gelation properties enable its use in various thermal-sensitive applications. HPMC's exceptional stability across different pH levels and its resistance to enzymatic degradation ensure reliable performance in diverse environmental conditions. Its non-toxic nature and biocompatibility have made it a preferred choice in medical applications, including ophthalmological solutions and tissue engineering.