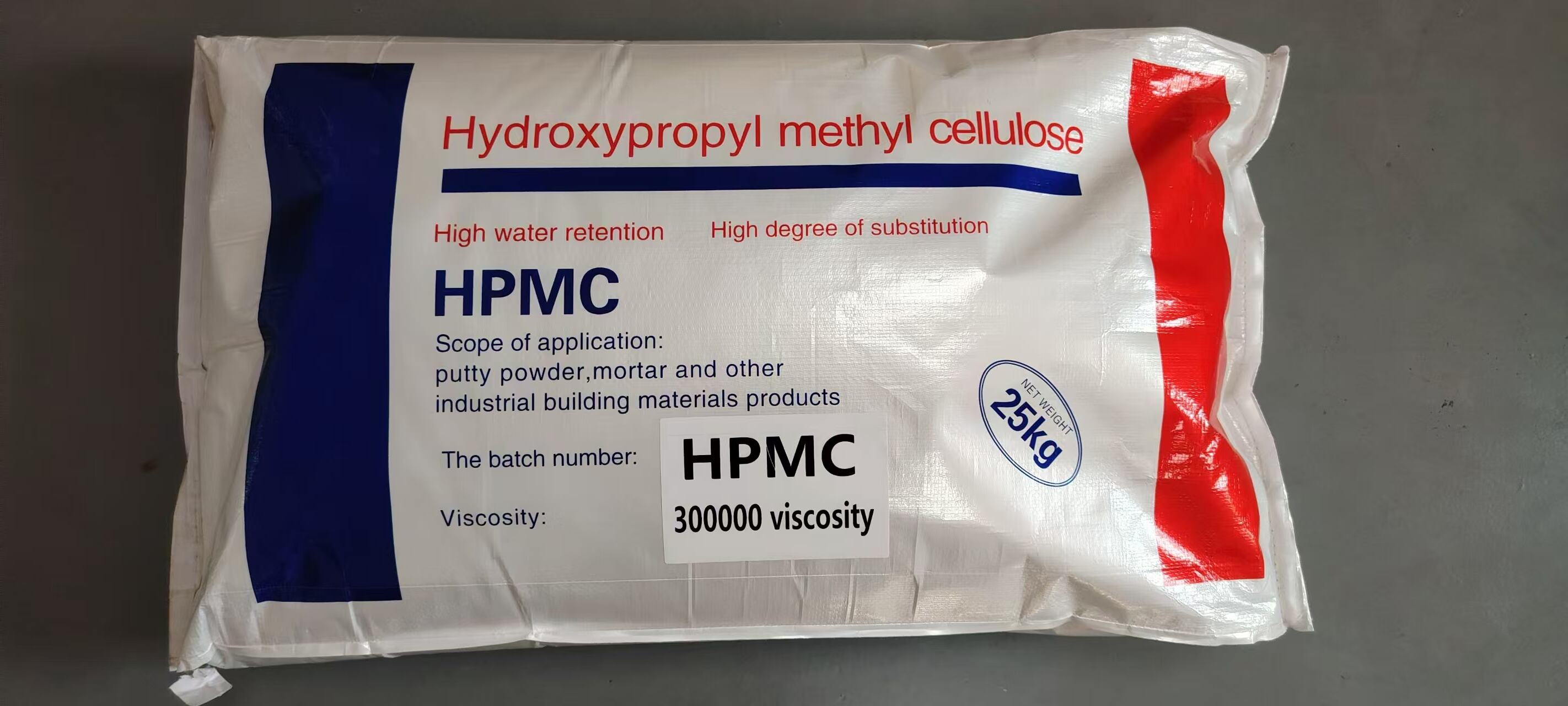

hydroxypropyl methylcellulose sigma

Hydroxypropyl methylcellulose sigma, commonly known as HPMC, is a versatile semi-synthetic polymer derived from cellulose. This advanced material serves as a crucial ingredient in various industries, particularly in pharmaceutical, construction, and food applications. Its molecular structure consists of modified cellulose ethers that provide exceptional stability and functionality across different temperature ranges and pH levels. The material exhibits remarkable properties including controlled viscosity, superior film-forming capabilities, and excellent binding characteristics. In pharmaceutical applications, HPMC sigma grade demonstrates exceptional performance as a drug delivery system, offering controlled release properties and enhanced bioavailability of active ingredients. Its water-soluble nature and ability to form clear, stable solutions make it an ideal choice for tablet coating, capsule manufacturing, and as a thickening agent in liquid formulations. The construction industry benefits from its properties as a cement modifier, improving workability and water retention in mortars and concrete mixtures. In food applications, it serves as an effective stabilizer and thickener, contributing to improved texture and shelf life of various products.