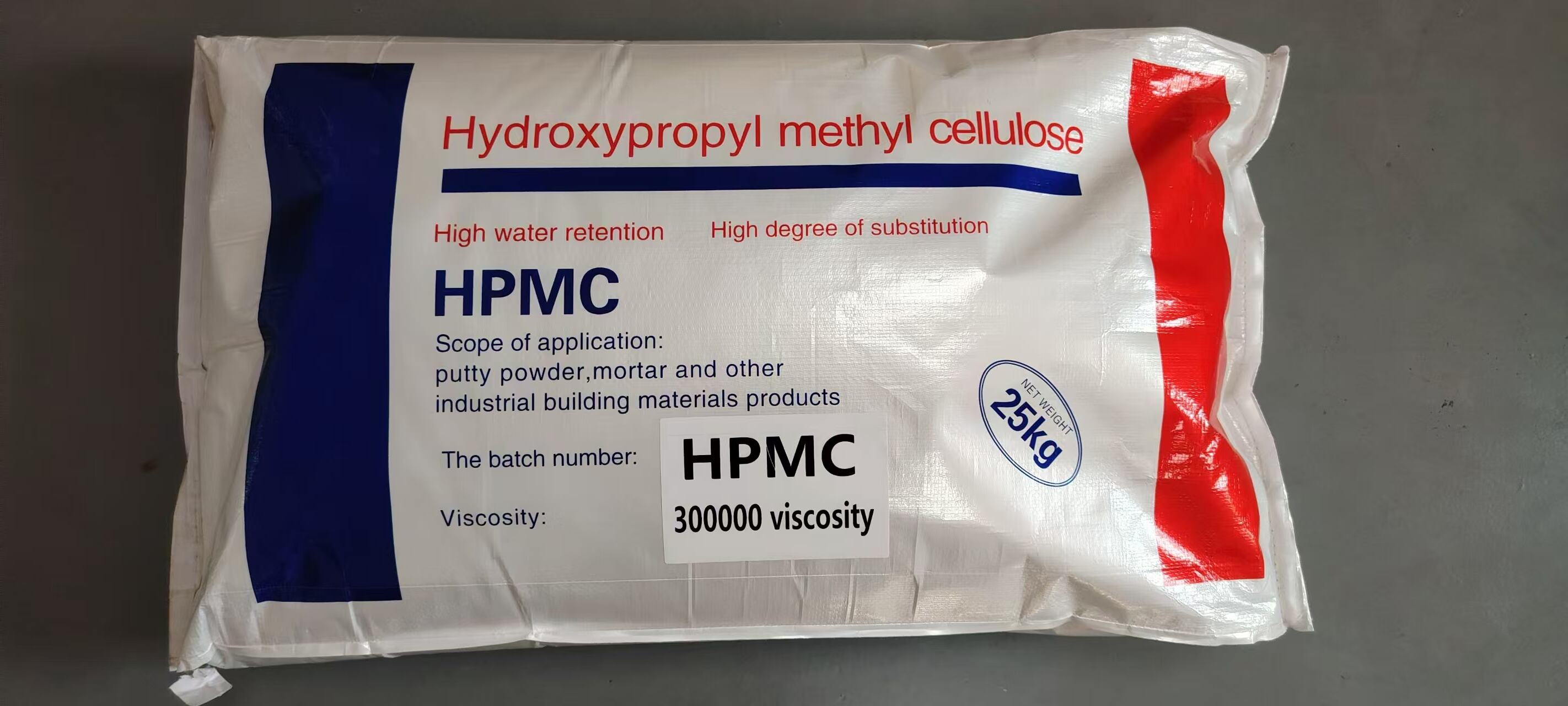

hydroxypropyl methylcellulose uses in construction

Hydroxypropyl methylcellulose (HPMC) serves as a vital component in modern construction practices, offering versatile functionality across various applications. This modified cellulose ether significantly enhances the performance of construction materials, particularly in cement-based products. In concrete and mortar applications, HPMC functions as a premium water-retention agent, ensuring optimal hydration during the curing process. It effectively controls water mobility within the mixture, preventing rapid moisture loss and promoting better cement particle distribution. The material's unique molecular structure enables it to form a protective colloid in aqueous solutions, improving workability and consistency of construction mixtures. HPMC's thickening properties help achieve ideal viscosity levels in cement-based materials, facilitating better application and finishing. Additionally, it acts as a powerful air-entraining agent, creating a stable microscopic air void system that enhances freeze-thaw resistance and overall durability. In tile adhesives and grouts, HPMC improves open time and adhesion strength, while in renders and plasters, it ensures better workability and reduced sagging. The material's chemical stability and compatibility with various construction chemicals make it an indispensable additive in modern building materials.