in tablet hydroxypropyl methylcellulose is used as

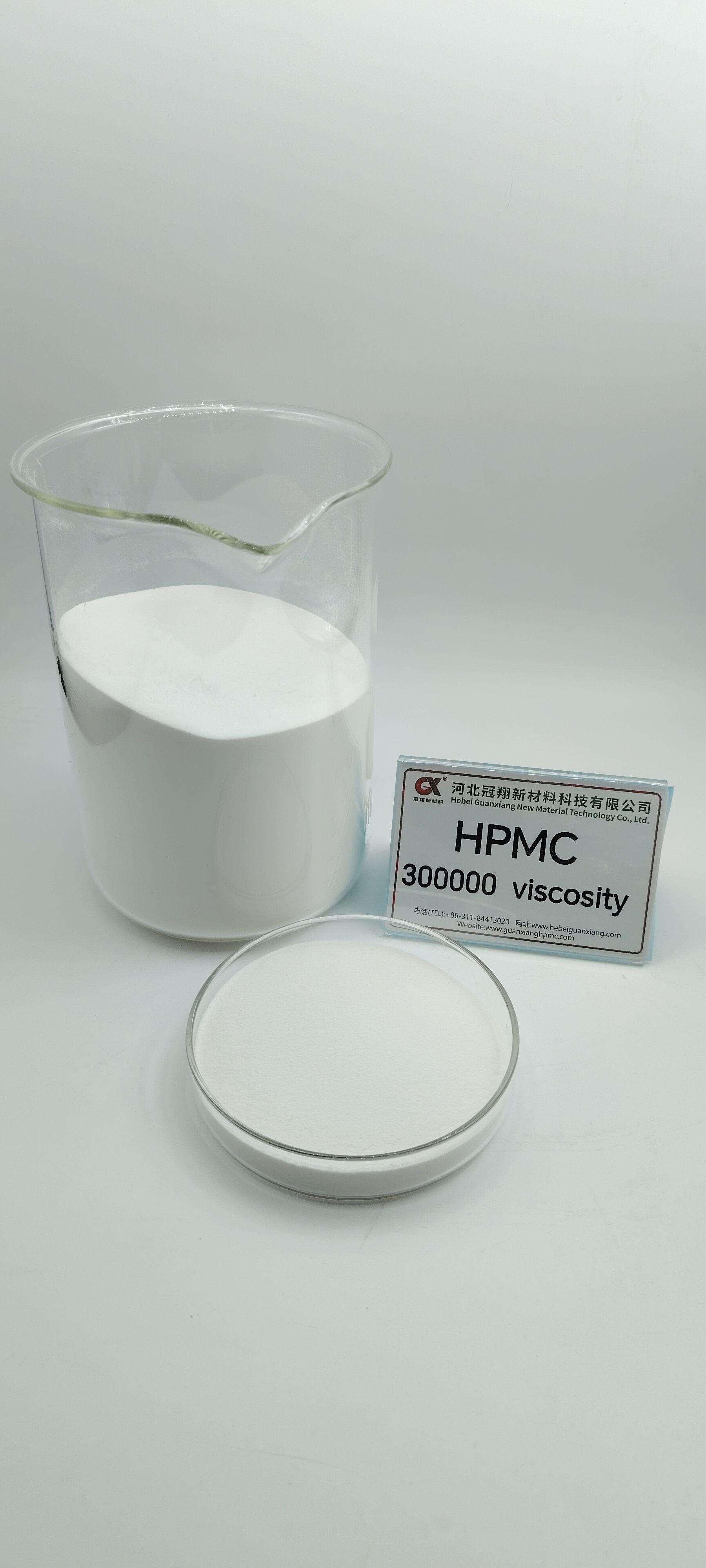

Hydroxypropyl methylcellulose (HPMC) serves as a crucial excipient in tablet formulation, functioning as a versatile binding agent and release modifier. In tablet manufacturing, HPMC is primarily used as a matrix forming material for controlled release formulations, providing essential functions such as binding, film coating, and modified release properties. Its unique chemical structure allows it to form a gel layer when in contact with aqueous media, controlling the release rate of active pharmaceutical ingredients. The polymer's viscosity grades range from 3 to 100,000 mPa.s, offering flexibility in formulation design. HPMC demonstrates exceptional stability across various pH conditions, making it suitable for diverse drug delivery applications. Its non-toxic nature and compatibility with numerous active ingredients have established it as a preferred choice in pharmaceutical manufacturing. The material's ability to form clear films and its excellent oxygen barrier properties make it particularly valuable in tablet coating applications. Additionally, HPMC's thermal gelation properties contribute to its effectiveness in sustained release formulations, where consistent drug release over extended periods is crucial.