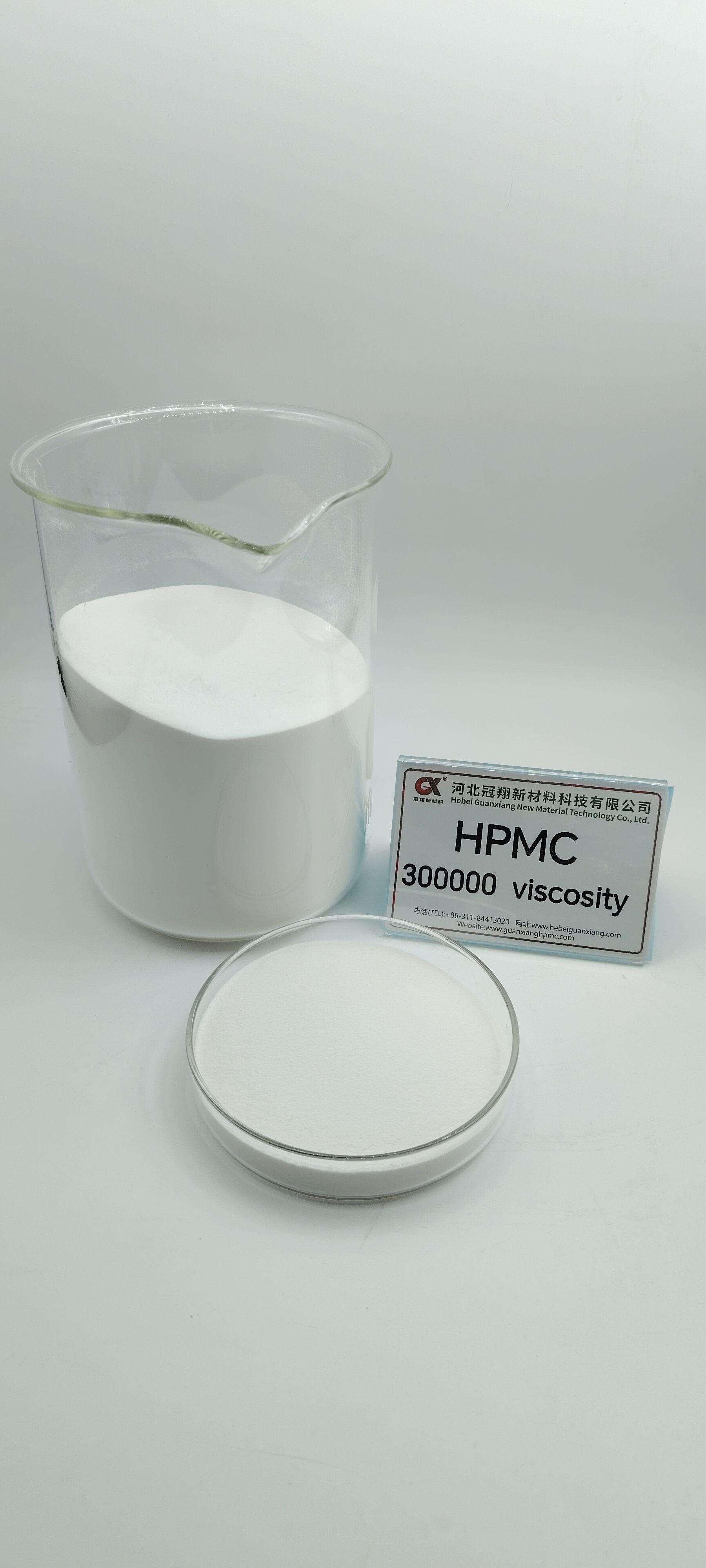

hydroxypropyl methylcellulose hpmc

Hydroxypropyl methylcellulose (HPMC) is a versatile semi-synthetic polymer derived from cellulose, widely recognized for its exceptional properties in various industries. As a non-ionic cellulose ether, HPMC exhibits remarkable film-forming capabilities, superior water retention, and excellent binding properties. This compound features a unique molecular structure that combines both hydroxypropyl and methyl substitution groups, enabling it to function effectively as a thickener, binder, film former, and stabilizer. In pharmaceutical applications, HPMC serves as a crucial excipient in controlled-release drug delivery systems, providing consistent dissolution rates and enhanced bioavailability. The construction industry utilizes HPMC as a vital additive in cement-based materials, improving workability, water retention, and adhesion properties. In food applications, it acts as an emulsifier and stabilizer, contributing to improved texture and shelf life. Additionally, HPMC's thermal gelation properties make it invaluable in various industrial processes, while its ability to form clear, flexible films has made it essential in coating applications.