hydroxypropyl methylcellulose e5

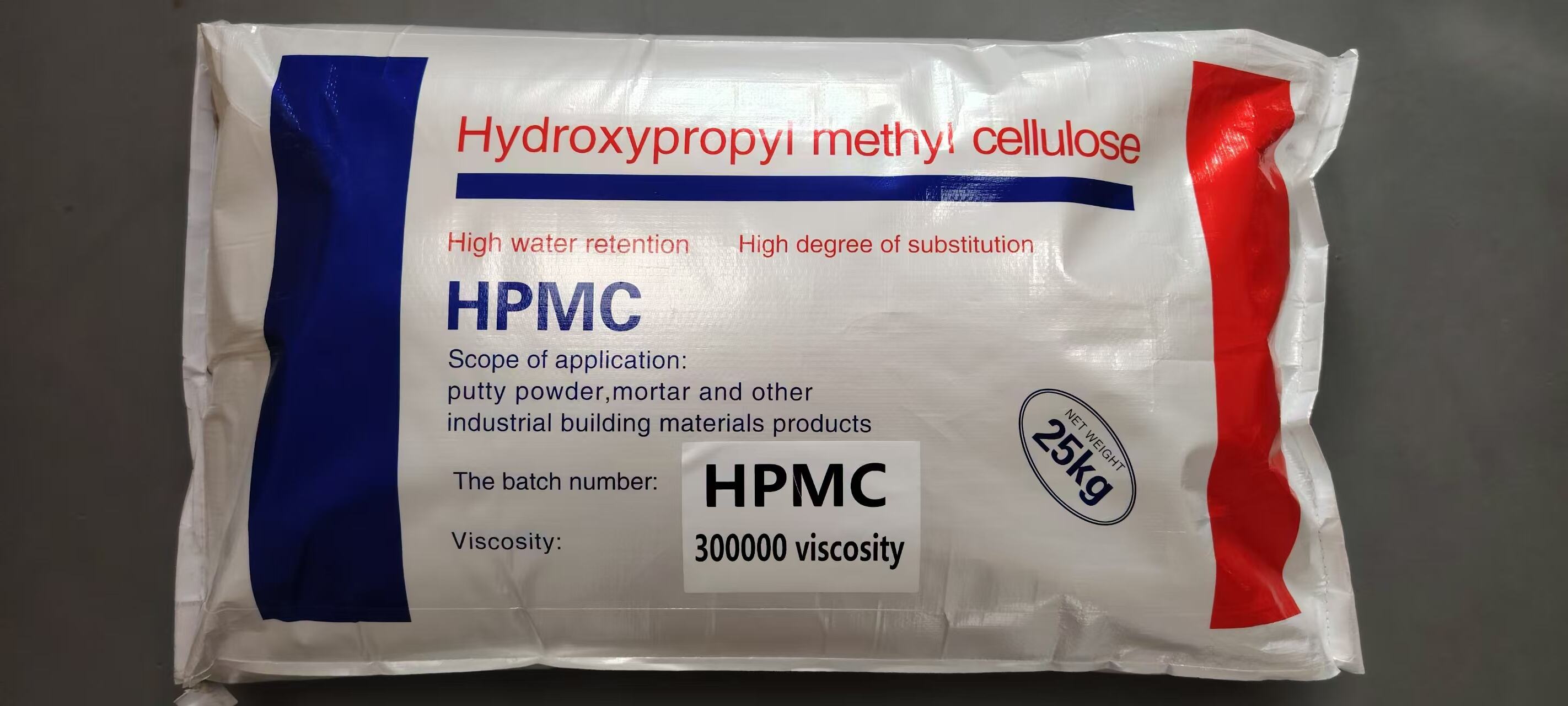

Hydroxypropyl methylcellulose E5 (HPMC E5) is a versatile cellulose ether derivative that plays a crucial role in various industries. This pharmaceutical-grade polymer is characterized by its excellent film-forming properties, controlled release capabilities, and superior binding characteristics. As a low-viscosity grade HPMC, E5 offers exceptional stability across different temperature ranges and pH levels, making it particularly valuable in pharmaceutical applications. The compound features a unique chemical structure that combines both hydroxypropyl and methyl substitution, resulting in optimal solubility and functionality. In pharmaceutical manufacturing, HPMC E5 serves as an essential excipient for tablet coating, providing a protective barrier while ensuring proper drug release. Its low viscosity makes it ideal for spray applications and allows for efficient processing in production environments. Beyond pharmaceuticals, HPMC E5 finds applications in construction materials, where it acts as a rheology modifier and water-retention agent. The material's controlled dissolution properties and ability to form clear, flexible films have made it indispensable in modern formulation development. With its proven track record in various applications and compliance with international pharmaceutical standards, HPMC E5 continues to be a preferred choice for manufacturers seeking reliable and versatile cellulose ether solutions.