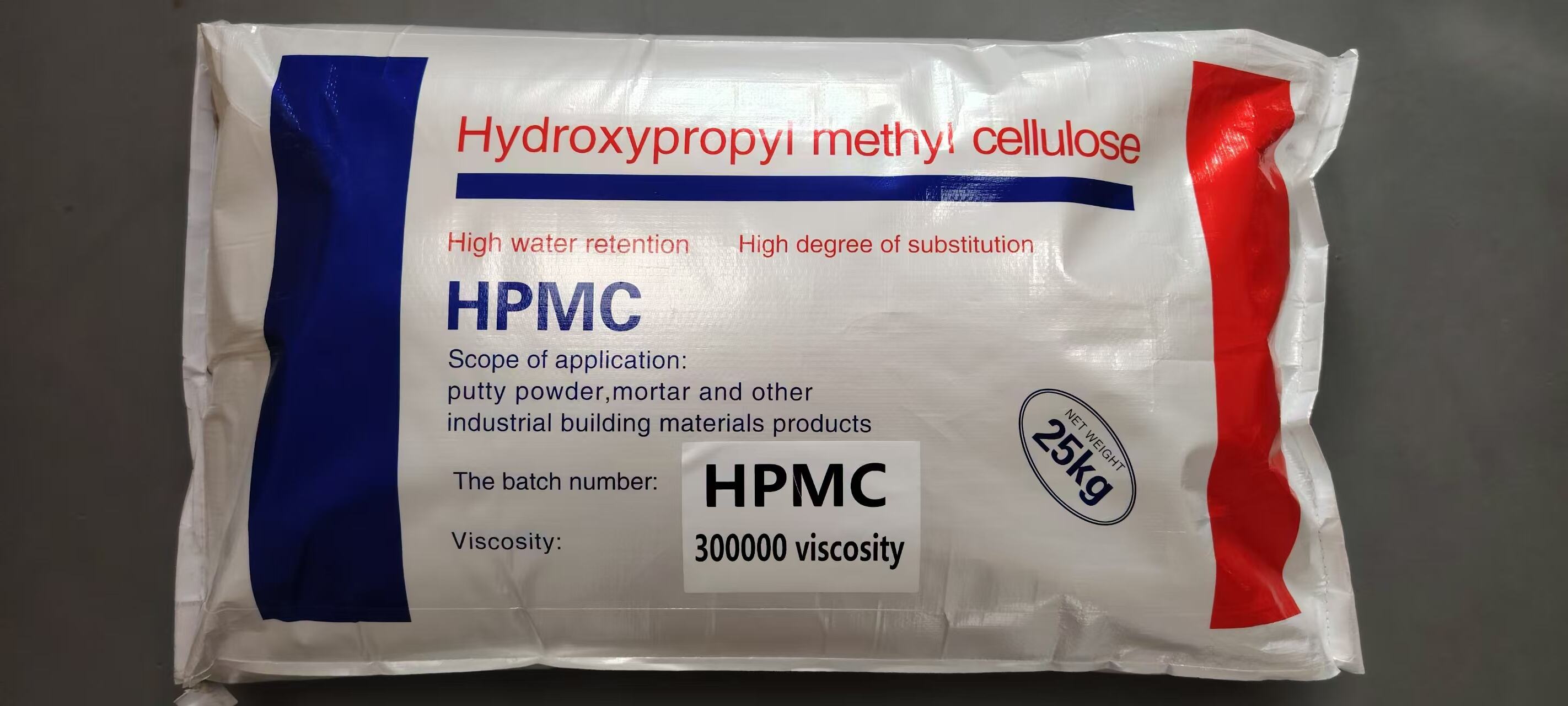

uses of hydroxypropyl methylcellulose

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer widely used across various industries due to its exceptional properties and adaptability. This cellulose derivative serves as a crucial ingredient in pharmaceutical, construction, food, and personal care products. In pharmaceuticals, HPMC functions as a controlled-release agent for drug delivery systems, forming a gel matrix that regulates the release of active ingredients. Its film-forming capabilities make it ideal for tablet coating, providing moisture protection and improving product stability. In the construction industry, HPMC acts as a highly effective water-retention agent and thickener in cement-based materials, enhancing workability and adhesion properties. Food manufacturers utilize HPMC as an emulsifier, stabilizer, and thickening agent, contributing to improved texture and stability in various food products. Its unique thermal gelation properties make it particularly valuable in vegetarian and vegan food applications. In personal care products, HPMC serves as a film former and thickening agent, contributing to the desired consistency and performance of various formulations.