hydroxypropyl methylcellulose is used in

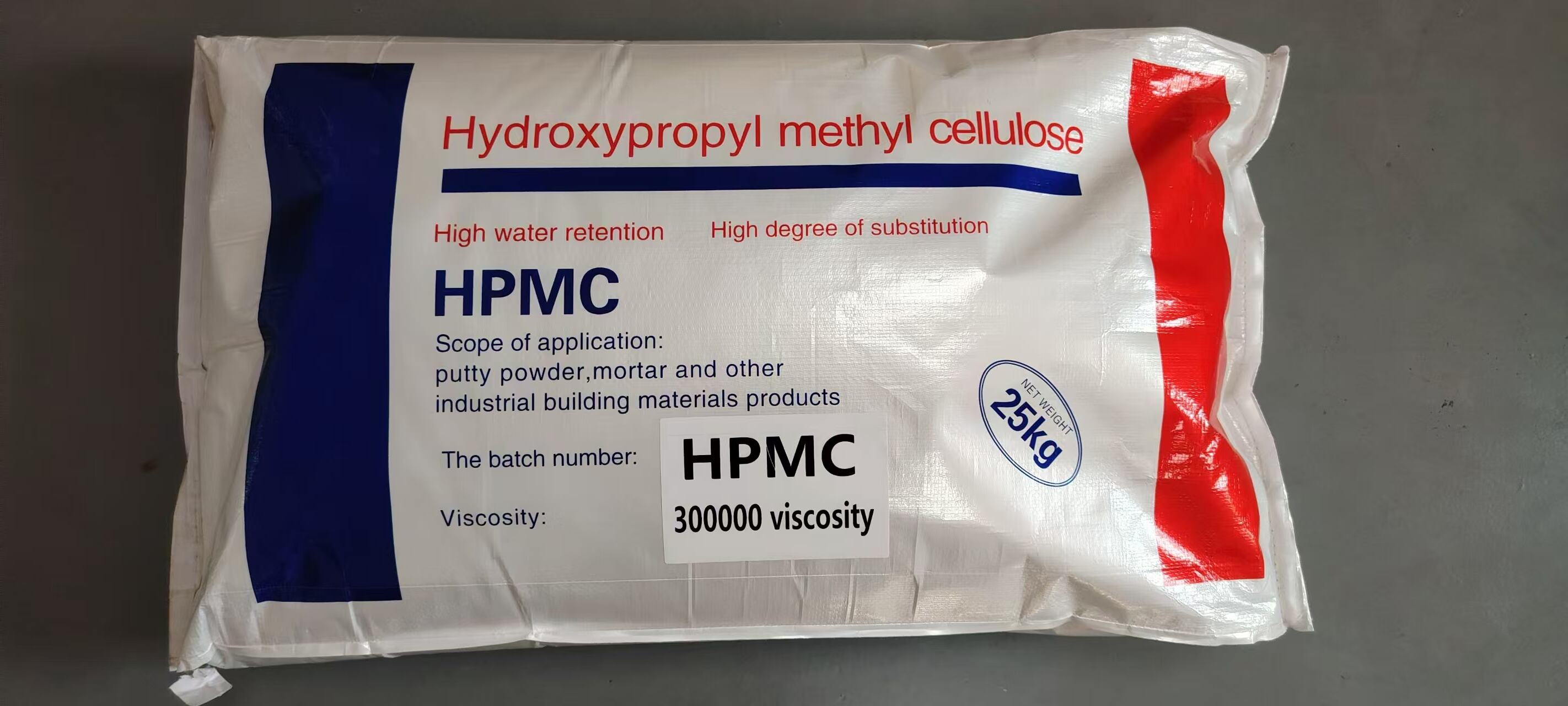

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether that serves as a crucial ingredient in various industries. This semi-synthetic polymer is derived from cellulose and modified with hydroxypropyl and methyl groups, resulting in a compound with exceptional properties. In pharmaceutical applications, HPMC functions as a controlled-release agent for drug delivery systems, coating material for tablets, and binding agent in capsule formation. The food industry utilizes HPMC as an emulsifier, thickener, and stabilizer, particularly in gluten-free and reduced-fat products. In construction, it serves as a vital additive in cement-based materials, improving water retention, workability, and adhesion. The compound's ability to form temperature-responsive gels makes it valuable in personal care products. Its film-forming capabilities and thermal gelation properties enable its use in ophthalmological solutions and as a substitute for animal-derived gelatin in vegetarian products. HPMC's molecular structure allows it to maintain stability across various pH levels and temperatures, making it ideal for diverse applications requiring consistent performance.